SEE PHOTOS

DESIGN:

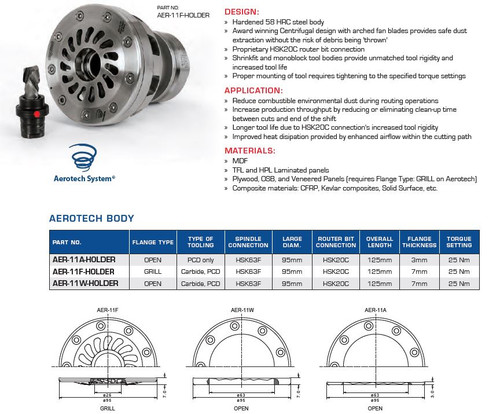

Optimized for Aerotech System only

Router bits are shrinkfitted into reusable HSK20C holders

3 precision ground cutting edges

Unmatched rigidity and near zero runout achieved by the shrinkfit connection

Good chipflow and low heat retention is achieved by the three semi-polished flutes

Increased cutting edge durability from special submicron, extended life carbide

30° helix design with bottom cutting capability

APPLICATION:

For exceptionally smooth finishing cuts

Reduced run-out in parting cuts as 2 cutting edges are engaged at all times

Increased number or bite marks per inch reduce chip size and provide a smooth finish, important when edge-banding without pre-milling

Eliminates chipping, fuzzing and tear-out when the end of the upcut and downcut cutting edges are more than 1/16" from the top and bottom surfaces

When cutting rebates, dados or pockets, use an upcut length that is at least 1/16" shorter than the shallowest cut

If part movement is a concern, use an upcut length of 4.8mm (0.188") or shorter

IMPORTANT:

Dust (Chips) must remain moderately loose and unpacked in the cut to achieve optimal dust extraction

High upcut design is recommended for maximum dust extraction

MATERIAL:

Excellent finish on:

Laminated panels

Chipboard

Good finish on:

Softwoods and Hardwoods

MDF

Plywood, OSB

(requires Aerotech flange Type: GRILL)