What is a Custom Band Saw Blade?

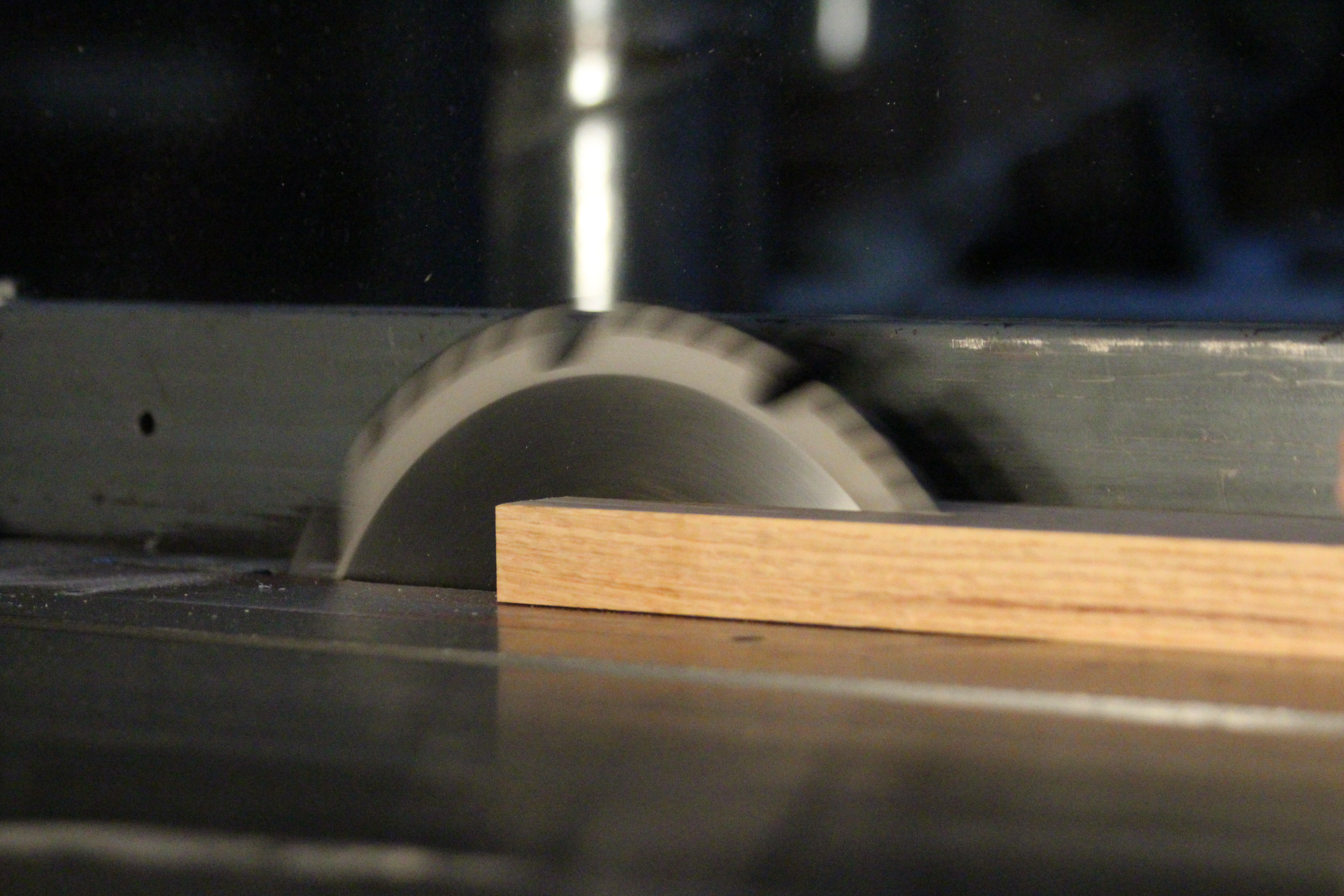

Custom band saw blades are tailored blades that meet unique requirements for length and other specifications. They’re great if you need them for specific tasks or to achieve certain results with your cutting.

We provide you with whatever length you need in a blade. Our custom band saw blades are made in Germany and offer you the durability to take on any cutting project without worrying about inaccuracy.

Know Your Band Saw Blades

Custom band saw blades aren’t simple to understand but checking a few simple things can ensure you make the right pick.

- Blade Material

- Tooth Configuration

- Blade Width

- Tooth Per Inch

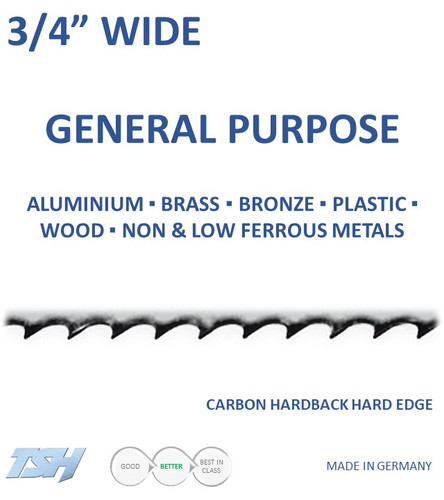

✔ Carbon Steel: Perfect for wood, plastic, and non-ferrous materials.

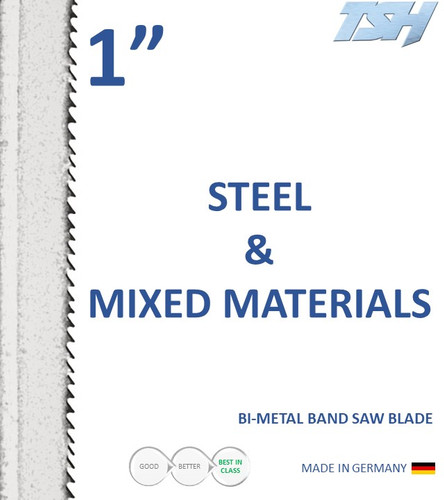

✔ Bi-Metal: Ideal for cutting metals and combination materials.

✔ Carbide-Tipped: Offers the most durability against steel and composites.

✔ Standard Tooth: Evenly spaced teeth, suitable for general-purpose cutting.

✔ Skipped Tooth: Wide-spaced teeth to prevent snagging on soft materials.

✔ Hooked Tooth: Provides a deeper gullet to cut through thicker materials.

✔ Wider blades are generally used for straight cuts that need stability.

✔ Narrower blades work well with tight cuts with high intricacy.

✔ Lower TPI (2-3): Usually for faster cuts with a rougher finish.

✔ Medium TPI (5-9): Well-paced cuts with more stability.

✔ Higher TPI (14-19): Slower cuts that offer a smooth finish.

Measure Your BandSaw Length

We offer custom-length bandsaw blades based on the requirements you provide. But, for accurate fits - it’s important to know how to measure the length of your bandsaw blade. For starters, turn your saw off and make sure it is not plugged in.

Then, follow these steps:

- Measure the Path: Use a flexible measuring tape to wrap around the entire blade path, including wheels and any tension adjustments.

- Account for Adjustments: Most band saws have tensioning mechanisms allowing minor size variations. Take note of the range specified in your saw’s manual and ensure your measurement falls within it.

- Consult the Manual: If measuring isn’t an option, check the saw’s manual or the manufacturer’s website for the recommended blade length.

That’s all you need to know to get the perfect blade from us!

FAQs - BandSaw Blades

To find the right blade length for your band saw consult the manual for a concrete answer. If you don’t have the manual, measure the existing blade to get a better idea or visit a professional.

Knowing the right size of blades is important when buying them online. Once you find the correct specifications, write it down with a permanent marker inside your machine. This will help you for next time!

Custom band saw blades are often tailored to meet specific requirements that work with different materials or for different uses. These blades can have an altered length, tooth shape, and TPI. We offer both metal and mixed-material custom band saw blades.

You should replace your band saw blade if you notice it chipping, performing unstably,rusting, or requiring excessive pressure.

Being a consumable item, any bandsaw blade will eventually require replacement with regular use, however there are a few things that can help to extend their life. Most importantly, make sure you are using the right width, type, and TPI for the job. Keeping buildup and debris from collecting around the blade and machine to allow for smooth operation. Lubricants are recommended when it is possible (Eg. flood coolant or anti-gumming for non ferrous materials.). Once you notice a fatigue crack or missing teeth, make sure you have a replacement blade ready to avoid downtime.