SEE PHOTO

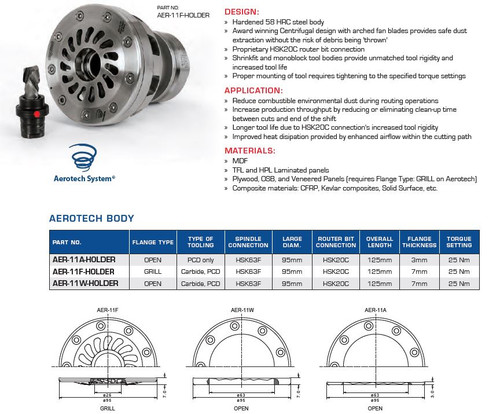

DESIGN:

Hardened 58 HRC steel body reduces wear

Award winning Centrifugal design with arched fan blades provides safe dust extraction without the risk of debris being 'thrown'

Hydraulic clamping chamber provides exceptional clamping power and significantly reduced run-out.

Universal clamping of standard cylindrical shank tools

20mm clamping diameter can be reduced with precision sleeves to accept smaller h6 shank diameters

SK30 taper is usable on ISO30 and BT30 spindle type machines. Thermwood machines require a standard ISO30 toolholder gripper fork to be installed

Proper clamping of tool shanks requires tightening to the specified torque settings

APPLICATION:

Reduce combustible environmental dust during routing operations

Increase production throughput by reducing or eliminating clean-up time between cuts and end of the shift

Fast tool changes

Longer tool life due to increased tool rigidity

Improved heat disipation provided by enhanced airflow within the cutting path

MATERIAL:

MDF

TFL and HPL Laminated panels

Plywood, OSB, and Veneered panels (requires Flange Type: GRILL on Aerotech)

Composite materials: CFRP, Kevlar composites, Solid Surface, etc.

REPLACEMENT PARTS:

AER-TW-10NM 10Nm Torque Wrench 5mm Hex Drive