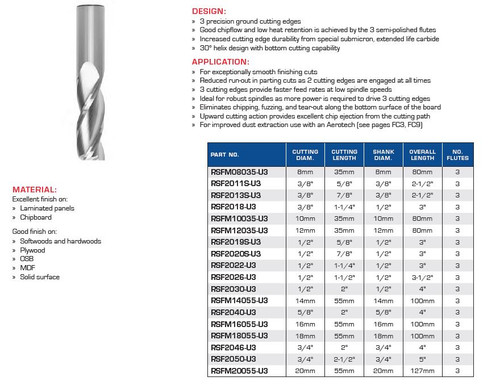

SEE PHOTOS

DESIGN:

3 precision ground cutting edges

Good chipflow and low heat retention is achieved by the three semi-polished flutes

Increased cutting edge durability from special submicron, extended life carbide

30° helix design with bottom cutting capability

APPLIACATION:

For exceptionlly smooth finishing cuts

Increased number of bite marks per inch reduce chip size and provide a smooth finish, important when edge-banding without pre-milling

Reduced run-out in parting cuts as 2 cutting edges are engaged at all times

3 cutting edges provide faster feed rates at low spindle speeds

Ideal for robust spindles as more power is required to drive three cutting edges

Eliminates chipping, fuzzing, and tear-out when the end of the upcut and downcut cutting edges are more than 1/16" from the top and bottom surfaces

When cutting rebates, dados or pockets use and upcut length that is at least 1/16" shorter than the shallowest cut

If part movement is a concern, use an upcut length of 4.8mm (0.188") or shorter

When possible select a router bit with a longer upcut length to improve chip ejection from cutting path

For improved dust extraction use with an Aerotech

MATERIALS:

Excellent finish on:

Laminated panels

Chipboard

Good finish on:

Softwoods and hardwoods

Plywood

OSB

MDF

HPL

Solid surface

LINEAGE XLC:

Extended life resharpenable coating