SEE PHOTO

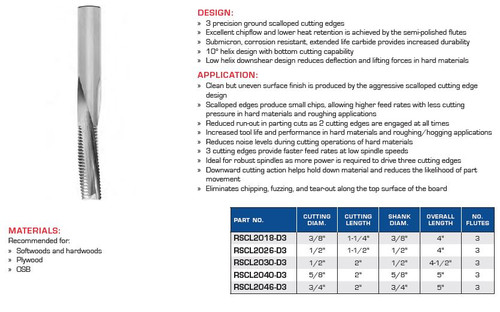

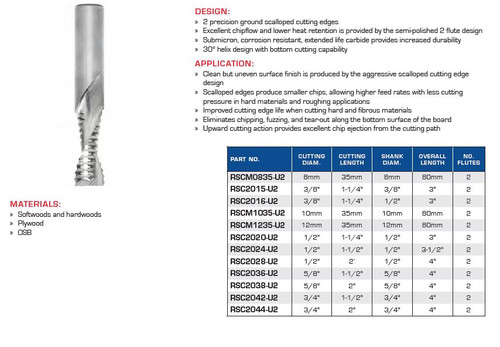

DESIGN:

3 precision ground cutting edges

Special chipbreakers for phenolic reduce cutting pressure and noise levels

Excellent chipflow and lower heat retention is achieved by the semi-polished flutes

Submicron, corrosion resistant, extended life carbide provides increased durability

10° helix design with bottom cutting capability

APPLICATION:

Improved cutting edge life and feed speeds when sizing/rough cutting phenolic

Chipbreakers specifically designed to provide increased tool life, and lower noise levels when cutting phenolic

Reduced run-out in parting cuts as 2 cutting edges are engaged at all times

Ideal for robust spindles as more power is required to drive 3 cutting edges

3 cutting edges provide faster feed rates at low spindle speeds

Eliminates chipping, fuzzing, and tear-out along the top surface of the panel

Downward cutting action helps hold down material and reduces the likelihood of part movement

MATERIALS:

Recommended and optimized for:

Phenolic