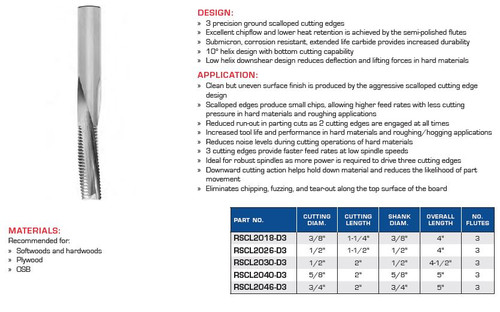

SEE PHOTOS

DESIGN:

3 precision ground scalloped cutting edges

Excellent chipflow and lower heat retention is achieved by the semi-polished flutes

Submicron, corrosion resistant, extended life carbide provides increased durability

10° helix design with bottom cutting capability

Low helix upshear design reduces deflection and lifting forces in hard materials

APPLICATION:

Clean but uneven surface finish is produced by the aggressive scalloped cutting edge design

Scalloped edges produce small chips, allowing higher feed rates with less cutting pressure in hard materials and roughing applications

Reduced run-out in parting cuts as 2 cutting edges are engaged at all times

Increased tool life and performance in hard materials and roughing/hogging applications

Reduced noise levels during cutting operations of hard materials

3 cutting edges provide faster feed rates at low spindles speeds

Ideal for robust spindles as more power is required to drive three cutting edges

Upward cutting action provides good chip ejection from the cutting path

Eliminates chipping, fuzzing, and tear-out along the bottom surface of the board

MATERIALS:

Recommended for:

Softwoods and hardwoods

Plywood

OSB