SEE PHOTO

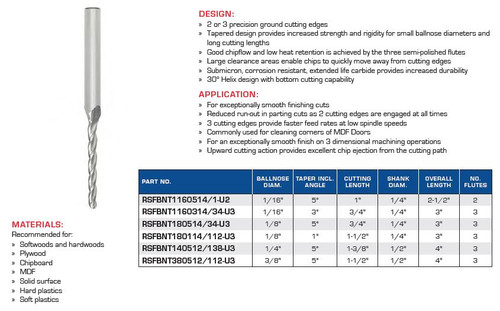

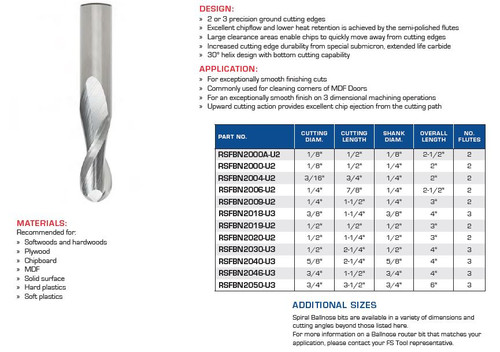

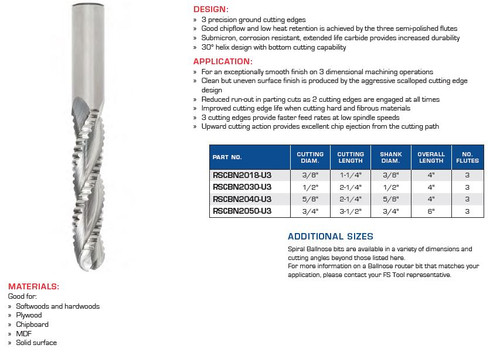

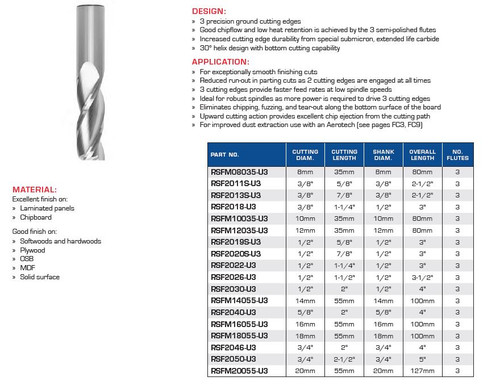

DESIGN:

2 or 3 precision ground cutting edges

Tapered design provides increased strength and rigidity for small ballnose diameters and long cutting lengths

Good chipflow and low heat retention is achieved by the three semi-polished flutes

Large clearance areas enable chips to quickly move away from the cutting edges

Submicron, corrosion resistant, extended life carbide provides increased durability

30° helix design with bottom cutting capability

APPLICATION:

For exceptionally smooth finishing cuts

Reduced run-out in parting cuts as 2 cutting edges are engaged at all times

3 cutting edges provide faster feed rates at low spindle speeds

Commonly used for cleaning corners of MDF doors

For an exceptionally smooth finish on 3 dimensional machining operations

Upward cutting action provides excellent chip ejection from the cutting path

MATERIALS:

Recommended for:

Softwoods and hardwoods

Plywood

Chipboard

MDF

Solid surface

Hard plastics

Soft plastics